Dresspack Systems

Mechatronic peripherals for industrial robots

Cable packages in use

-

SUMOTEX

-

SUMOSLIDE

-

SUMOFLEX

Overview

A reliable power supply and data connection are crucial in the industrial production environment, which is why it’s all the more important to ensure that the appropriate robot peripheral products are used in a manner that meets the requirements, as incompetently optimised robot installations can result in higher wear and tear or even a complete production shutdown.

Due to our extensive experience gathered over many years, we at Sumcab are familiar with the various types of industrial robots and the areas in which they are deployed. Rather than providing standard products, we make it our business to design bespoke solutions in a rapid and flexible manner.

We develop, optimise and install everything from pre-wired dresspack systems to robot-guided tools and portable teach panels for a reliable production process that exploits the full potential of their robot system.

Assembling the dresspack systems is only part of our service offering. The basis for a reliable dresspack system can only be ensured by a professional installation. SUMCAB maintains a team of competent and experienced service engineers dedicated to this task.

NEW RETRACTION SYSTEM TYPES

We have developed a variable modular concept with our new SUMOSLIDE (Sumcab Motion Slide) and SUMOFLEX (Sumcab Motion Flex) retraction systems that enables us to implement individually tailored hose package installations for a wide range of applications.

SUMOFLEX (Sumcab Motion Flex)

Flexibly adaptable dresspack guidance

SUMOFLEX is a classic retraction system with a compression spring mounted on the corrugated tube. It is suitable for corrugated pipe diameters of 36, 48 and 70.

The advantage of this system is its modular design: both the corrugated tube diameter and the length of the pluggable retraction tube, and, therefore, also the spring travel, can be selected flexibly.

Thanks to this modular principle, the SUMOFLEX system can be planned in different lengths to cater to any pinch points around the robot. It provides a high degree of adaptability and is available in a wide variety of designs and assembly variants.

Dresspack systems can be replaced without tools using screwless system holders.

Benefits of the System

- Modular system for maximum flexibility: variable corrugated tube diameter and plug-in retraction tube length

- Maintenance-friendly

- Robust and low-wear

System Components at a Glance

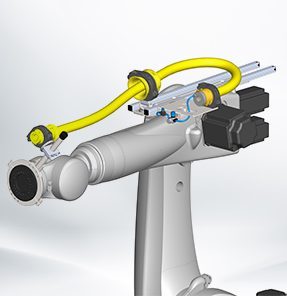

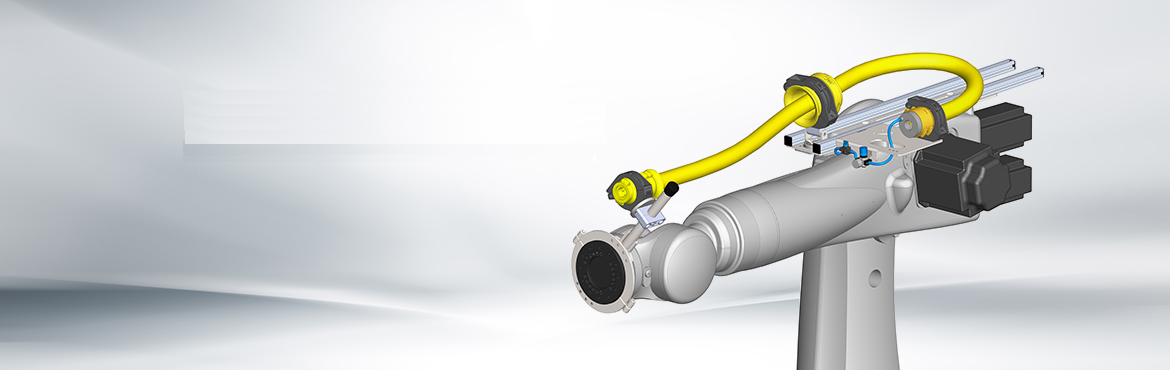

SUMOSLIDE (Sumcab Motion Slide)

Visible hose guide without corrugated tube

The SUMOSLIDE features an extremely compact design and a linear forward and backward

movement of the spring carriage. These design features prevent tight bending radii and looping on the robot. This makes the SUMOSLIDE ideally suited for guiding corrugated tubeless components such as suction hoses, feed hoses or heating hoses.

Due to its compact design, the SUMOSLIDE enables a slim guidance of the hose package on the robot arm, which reduces pinch points and the risk of wear and damage, making it the ideal solution for smaller installation spaces.

The screwless system holder enables the replacement of the guided cable or dresspack without tools.

Benefits of the System

- Variable expansion option due to prefabricated drilling pattern

- Low space requirement due to flat design

- Ideal for guiding feed hoses

- For smaller installation spaces

- Twin and multiple solutions possible

- Maintenance-friendly

SUMOTEX TM (Sumcab Motion Textil

The power & media supply system

Overview

Sumcab SUMOTEXTM – the most reliable and durable energy supply

energy supply solution on the market.

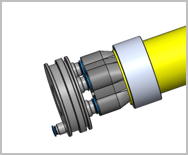

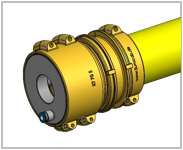

The SUMOTEXTM relies on pneumatic pressure, integrated in a specially developed high-tech textile sheath, to realise the necessary reset effect - without any significant loss of compressed air.

This process is patented by DAIMLER AG and realised under licence by Sumcab Robotics.

The combination of innovative design and resistant construction materials reduces frictional resistance on the robot to a minimum. This makes the SUMOTEX extremely reliable and, above all, particularly durable.

Axis 3 compressed air supply - side view

Continuous pressurisation with compressed air is not required. Once filled, the system operates stably with a minimum compressed air loss of 2% after 30 days of continuous operation

Compressed air supply axis 3 - fully assembled

Our Services

Taking account of application-specific requirements and individual location factors, we develop, optimise and install everything from pre-assembled dresspack systems to robot-controlled tools and portable teach panels.

All of this builds upon our dresspack system: perfectly coordinated components such as dresspack system ducting and conduit, the SUMOFLEX/SUMOSLIDE cable retraction system and various support components can be combined for a wide variety of robot-related applications and, therefore, assembled to cater to specific customer requirements.

This enables us to assemble dresspack systems for practically every conceivable application including, for example:

- Stud welding

- Laser welding

- Spot welding

- Self-piercing riveting

- Glueing applications

- Bolting applications

- Clinch applications

- Coating systems

- In-line measuring

- PVC application systems, GAD, FAD

- Acrylate processing systems, SDM

- Wax-based cavity sealing systems

- Bespoke solutions in the above-mentioned areas (ultrasound-based PVC robot-controlled scraper cleaning systems)

- System utilisation in dirty environments (e.g., sandblasting, milling, foundry environments)

- Overhead power supply

- A handling application combined with supplementary electronic bolting technology

- A laser welding application with an integrated suction hose

- A handling application combined with additional high-pressure hoses for the hydraulic operation of a mechanical joining system

- A glueing application with, for example, dual-component material positioning at the dispensing head

Our services at a glance

-

1. Individual Consultancy

that takes account of the specific robotic application and prevailing site conditions

-

2. Assembly

of the dresspack systems – customised to client specifications

-

3. Installation

on site by our own professional service engineers

-

4. Optimisation

of existing plant to increase system uptime

-

5. Final Check

of existing plant to increase system uptime

-

6. Preventative Maintenance

analysis of the location factors specific to your system and preparation of a customised integrated maintenance schedule based on our findings

-

7. Repair Management

Qualified repair of your dresspack system - rapid, professional and cost effective

Your Benefits

-

Universal

Sumcab dresspack systems can be used with almost any model of robot. The system was designed to work with any application and tool type and can be tailored to our customers’ specific requirements, providing planning reliability and saving customisation costs.

-

Maximum Flexibility

The dresspack system’s compact construction reduces awkward contours and the risk of wear and damage. The thin-profile construction of the SUMOFLEX/SUMOSLIDE retraction system also makes it possible to assemble dual or multiple application solutions in a rapid and cost-effective manner using standard components.

-

Service Friendly

The system is quick and easy to open for servicing or repairs. The entire dresspack systems can be swapped out within just a few minutes, which reduces system downtime and the associated costs.

-

Single Source

From the assembly of the dresspack systems to the installation of the individual components and subsequent maintenance management, you can source everything directly from SUMCAB – quick, reliable and customer oriented.

-

First-class Service

It is not always possible to install an application-specific power supply to industrial robots using standard cabling products. The Sumcab service team has the relevant expertise to develop and assemble bespoke cabling solutions based on specific robot models and taking into account all system conditions and requirements as well as the prevailing environmental influences.

-

Simulation Service

At your request we are able to produce 3D volume models up to and including cinematic CAD-based power supply models to facilitate your feasibility studies and clash-condition analyses at the system planning stage using relevant simulations.

We're Here for You

Our mission at Sumcab Robotics is to provide our customers with rapid, reliable and customer-oriented technical solutions in the form of high-quality products and services.

Do you have any questions or would you like more information about our products and services? Then simply get in touch with us, using either the contact details above or our contact form. We'll get in touch with you without delay!