Special Cables

Overview

SUMCAB offers a single source for all your requirements from product development to prototyping to the packaged and pre-assembled connection-ready cable.

We design products to the highest possible quality so that you can focus on your core business. Innovative, Reliable and Forward-Looking We don’t just produce cables - we come up with solutions.

The highly flexible applications common in the robotics industry place high demands on the mechanical, chemical and thermal durability of the installed robot cable systems, which must withstand millions of bending, torsional, and traction cycles in addition to being resistant to a plethora of environmental influences.

SUMCAB Robotics specialises in the development and manufacture of specialised robotics cabling, which must cater to precisely these demands.

As a subsidiary of the Spanish SUMCAB Group, we can draw upon 20 years of know-how in special cable production. Production takes place in Spain's first ever cable factory, a state-of-the-art production centre, which enables us to work with a wide variety of raw materials and to develop products of the highest possible quality, which naturally comply fully with the relevant ROH and Reach guidelines and all other applicable standards.

The SUMCAB Group prioritises the quality of its products and services above all else. By investing effort and resources in the quality and longevity of our products we continuously optimise our production processes, thus maintaining an outstanding price-performance ratio.

All our cables and power leads are constructed, produced, tested and refined with the greatest possible care. We can produce prototypes starting at 100 m and serial products starting at 300 m with extremely short lead times of just 3 weeks!

Our product and service portfolio includes everything from unpackaged cables (sold by the metre) for chain cable carriers and robotics applications to special connection-ready cables, such as robot connector and positional-axis-arm cables for teach panels, to the development of bespoke cabling systems tailored to specific customer requirements.

In relation to the latter, we offer a comprehensive service palette covering everything from initial design to prototyping, small-scale and serial production, testing and validation of the finished cables in our in-house test lab and, if desired, on-site component installation at the customer's premises.

Special Cables by the Metre

Due to the continuous bending to which they are subjected, power leads for chain cable carriers and robot applications have to have excellent mechanical strength. We’ve developed the Sumodrive® and Sumflex® Mechatronic product ranges specifically for this application area. Compared to traditional products, these cables can withstand millions of bend, torsion and traction cycles and are, in addition, resistant to a wide range of environmental influences.

To guarantee the quality and reliability of our special robotics cabling systems, we subject them to a comprehensive quality control and functional inspection regime.

Signal and data cabling

-

Sumodrive® 410

-

Sumodrive® 410 C

-

Sumodrive® 412

Power supply and control cabling

-

Sumodrive® CP 2100

-

Sumodrive® CP 2100 C

-

Sumodrive® CP 510

Encoder and resolver cabling

-

Sumodrive® 710 C

-

Sumodrive® 720 C

Motor cabling

-

Sumodrive 910 C

-

Sumodrive 920 C

Data transmission cabling

-

Sumodrive® 4.0 Profinet PNP-C5

-

Sumodrive® 4.0 Industrial Ethernet EIP-C5

-

Sumodrive® 920 C

Robotic application cabling

-

Sumflex® Mechatronic

-

Sumflex® Mechatronic HFS

Connection-Reading Special Cables

Connector, Adaptor and Extension Cables for Teach Panels

The connector cable between the controller cabinet and the portable teach panel has to reliably fulfil its operating functions over the long term. In addition to voltage and control signals, safety-related process functions for the enabling switch and emergency off switch must transmitted reliably. We offer a large selection of relevant connection-ready cabling systems that are compatible with almost all controller generations on the market

and designed to meet the quality, reliability and conformity requirements specified in the various manufacturer standards. All components undergo extensive quality and functionality checks – our QA documentation can be provided on request.

Our connection and extension cables for portable teach panels are available for robot controls systems from ABB, COMAU, FANUC, KAWASAKI, KEBA, KUKA, PANASONIC, REIS, STÄUBLI, SIEMENS and YASKAWA in standard lengths of 10 m and 20 m for connection cables and 10 m, 15 m and 20 m for extension cables. We currently offer adapter cables for KUKA and SIEMENS robot control systems in lengths of 0.3 m (KUKA) and 0.2 m (SIEMENS).

Downloadable Brochures

-

Connector, Adapter and Extension Cables

read more

-

Connector, Adapter and Extension Cables

read more

The Sumflex® Mechatronic Robot Connector and Positional Axis Arm Cables

The Sumflex® Mechatronic Robot Connection Cables were specially developed for the transmission of power output and control signals for the reliable operation of your robot's servomotors for the six positional axis arms.

In addition, the Robotic Connection Cable range includes an extensive assortment of cables with factory-fitted connections made to original manufacturer standards.

All cable types included in the range comply fully with the quality, certification and conformity requirements specified by the relevant manufacturer. All components undergo extensive quality and functionality checks – our QA documentation can be provided on request.

In addition to standard static installations in cable ducting, the 'Robot Connection Cables' are also designed for use in the drag chain of the robot's positional-axis-arm. Also included is a selection of prefabricated connector and control cables for the servomotor of the seventh standalone axis.

Bespoke Special Cables

Custom Designed to the Customer’s Requirements

Our customers’ requirements are highly complex and different from one another. Our candid and competent consultancy service will help you find the right, application-specific solution for maximum system uptime and efficiency.

Reliability and Quality

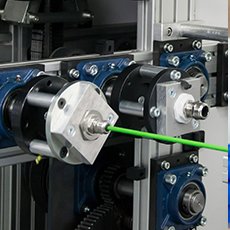

To ensure the reliability of our products, we have a technical laboratory equipped with our own 3D test system, which enables us to test how our cables perform under high acceleration and braking conditions and when subjected to continuous traction, compression, bending and torsion.

-

Bending

BendingThe cable is bent backwards and forwards.

-

Trailing

TrailingThe cable is subjected to bending and pulling, and to rapid acceleration and deceleration.

-

Torsion

TorsionThe cable is twisted around its axis.

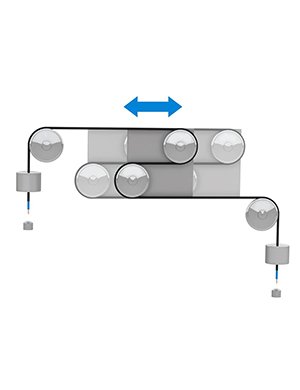

Line Test Device

The line test device is for inspecting the axial twisting (torsion) bending of robotics cabling as well as various field bus cables. We also provide the option of testing the torsion and bending parameters using a proprietary process. (3-D Test)

Any failures identified are included in a report following completion of the testing process. By using both a mechanical and electronic fault log, we safeguard the fault log in two ways.

A failure point analysis can then be run on the tested cable for a more detail cause analysis. In this case too, the customer receives a detailed report including cable structure and routing optimisation suggestions.

Technical data from the line test device:

-

Maximum line test length1000 mm (horizontal testing only)

-

Cable diameterUp to 28 mm cable diameter

-

Maximum rotation speed35 rpm

-

Maximum rotation range± 180º

-

Temperature range for the testRoom temperature

-

Internal fault logDouble safeguarding through mechanical and electronic fault logging as well as dynamic conductor testing

-

On screen error indication144 conductors (simultaneous testing of up to five cables)

-

Power supply1 x 230 V - 50 Hz

-

Dimensions (l x w x h)3,000 x 1,500 x 1,500

-

Mechanical construction ofaluminium / steel

Cable Eye®

The pin assignment of any cable system can be tested with the Cable Eyes®.

Almost every plug connection can be tested. We will check your galvanic connection, throughput, continuity, cable assignment, wrong wiring, resistance and more.

Following the test, a digital report is generated which shows the measured values.

Up to 128 conductors can be tested simultaneously using the Cable Eyes®, and, due to the highly flexible test system, more if required.

YOUR BENEFITS

-

Rapid response and short delivery times

We at SUMCAB are always striving to help our customers find a solution in a rapid and flexible manner. We can provide you with customer-specific special cabling within extremely short lead times starting at just 3 weeks.

-

Bespoke Solutions

Our skilled technical team analyses the application-specific requirements in minute detail and develops the optimum solution in collaboration with the customer. We'd love to work with you to develop optimum solutions to meet your needs!

-

In-House Testing Centre

Cables are tested for safety-related and technical properties, such as combustion behaviour, torsional, traction and bending resistance, in our own 3D test system at our technical laboratory.

-

Prototypes and Small-scale Production

We can produce prototypes starting at 100 m and serial products starting at 300 m with extremely short lead times of just 3 weeks!

-

Broad Product Range

Our product portfolio includes flexible and highly-flexible cables and lines to meet demanding electrical, mechanical and safety-related requirements. Whether used with robots or drag chains or in hybrid cabling scenarios, SUMCAB provides bespoke solutions precisely tailored to your specific requirements.

-

Products of the Highest Quality

Drawing upon a plethora of combinable materials and auxiliary supplies, a reliable manufacturing technology and international licensing arrangements, we can produce high-quality customer-specific special cabling in short order.

I’m here for you

Contact Person

Our mission at SUMCAB Robotics is to provide our customers with rapid, reliable and customer-oriented technical solutions in the form of high-quality products and services.

Do you have any questions or would you like more information about our products and services? Then simply get in touch with us, using either the contact details above or our contact form. We'll get in touch with you without delay!